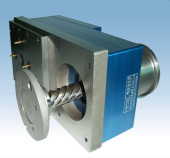

High precision tapping stroke is easy to adjust. The automatic reversing device can freely adjust tapping stroke. Shallow holes and low machined parts with holes can also be easily adjusted. The double safety device can prevent the damage of the screw tap

Bad. Double safety clutch is specially set for spindle rotation, up and down, and tool advance and retreat. The spindle can stop automatically, and the tool will not be damaged even if it reverses.

Pitch A and B gears are fully matched with the A and B rotating shafts and the main shaft according to the pitch, which are vertically stable, accurate and highly precise. The screws can move forward and backward freely without any effort when tapping. At the same time, it depends on excellent processing items, which will not cause different threads in thickness. Perfect threads can also be made for thin plates, light metals, synthetic resins and other soft products. At the same time, multi axis machine can be configured for multi axis synchronous machining, which greatly improves the production efficiency.

1. The spindle advance/retreat tool is automatically and precisely matched according to the tooth pitch, and the work will not float.

2. The operator's hands can leave the machine freely.

3. It can be used for high-speed continuous cycle operation and is durable.

4. Beginners can also operate smoothly.

5. High precision tapping stroke adjustment is simple.

6. The double safety clutch device can prevent the breakage of the tap.

7. The combination of multi axis tapping device can produce high efficiency operation.