|

-

The optimal formula of Lixiang die internal tapping machine is as follows: 1. We started tapping after the guide needle entered. 2. The stroke of our tapping machine is fixed. The tapping machine is not limited by the stroke of the punch, and the upper and lower dies are not connected. 3. The die tapping machine itself has a floating plate and an elastic guide structure, which makes the die simple. 4. Multi hole die internal tapping machine: the same machine can tap large and small teeth at the same time, such as several M3 and M4. 5. Our in mold tapping machine is complete and easy to install. 6. Our company has the ability to design and manufacture metal continuous molds! The existing mold can be repaired and upgraded to achieve the process of tapping in the mold and help customers reduce costs! That brother is in need!!! ADD: No. 115, Shajiaotou Village, Hongqi, Huihuan Town, Huizhou City http: www.zglixiang. com E-mail: poolzeng@126.comFM : Zeng Jia

-

With the rise of labor costs, the "demographic dividend" of labor-intensive enterprises is shrinking year by year. It has become the key to the economic development of one party to demand "technological dividend" from mechanization and automation. At present, the domestic stamping industry needs to process threaded hardware, and most manufacturers still stay in the traditional processing technology that wastes resources, such as manual tapping, automatic tapping machine, after single punching or continuous punching. The die tapping technology can cooperate with the automatic production of punch equipment to achieve the integrated production of stamping and tapping. Whether it is reducing staff, increasing efficiency or improving quality, the in mold tapping technology has brought great changes to hardware manufacturers. Figure 1 shows the working principle of the die tapping machine. Traditional tapping production mode Traditional tapping production mode is generally formed by single p

-

In recent years, the auto parts industry chain in China has risen. With the social development, the traditional manual tapping production line has not been able to meet the expansion of market demand. Although the investment in the initial stage of mold opening is small, many problems such as the low efficiency of manual tapping and poor product quality stability after the completion of stamping have increasingly affected the development of enterprises. Therefore, it is urgent to develop automatic internal tapping of continuous die for stamping. In China's traditional stamping automation industry, the market environment is deteriorating, no matter whether it is metal stamping at the bottom or auto parts stamping at the top. Many domestic manufacturers still use traditional manual tapping, which leads to low production efficiency. At present, there is still a certain gap between China's automation level and foreign first-line level. Therefore, the development of die tapping technology i

-

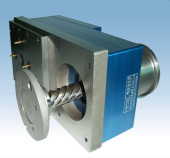

Tapping machine is a kind of mechanical processing equipment that processes internal threads, screws or thread fasteners on the inner side of the holes of various parts with different specifications of through holes or blind holes, such as machine shell, equipment end face, nuts, flanges, etc. Tapping machine plays an important role in manufacturing. Advantages of tapping machine: reduce working procedures and improve automation. The die internal tapping machine integrates the punching and tapping action of the parts to be tapped, and directly taps and punches on the punch simultaneously.

-

In the process of production and processing, sometimes the tapping speed slows down. Whether the tapping machine equipment is aging or the product quality is poor has become the first thing that came to mind. What factors affect the tapping speed of the tapping machine? In fact, there are many factors that affect the tapping of the tapping machine, such as: tapping material, type, number of teeth eaten, lower hole shape, cutting materials and cutting oil, etc. Therefore, these factors must be taken into account when selecting the automatic tapping machine. Because there is no chip in the tapping machine, the tapping speed of the extrusion tap can be faster than that of the cutting. At the same time, the factors such as the material to be processed, the cutting fluid, and the machinery should also be considered. Generally, the extrusion tap is used in 5-20m/MIN, which is similar to the punching and drawing process of the punch, and can reach a speed of more than 30m/min under special ci

-

Die tapping machine is a kind of mechanical processing equipment that processes internal threads, screws or thread fasteners on the inner side of the holes of various through holes or blind holes with different specifications, such as machine shell, equipment end face, nuts, flanges, etc. Die internal tapping machine is also called tapping machine, thread die internal tapping machine, thread tapping machine, automatic die internal tapping machine, etc. Tapping points of die tapping machine:

-

Tapping machine is a kind of mechanical processing equipment that processes internal threads, screws or thread fasteners on the inner side of the holes of various parts with different specifications of through holes or blind holes, such as machine shell, equipment end face, nuts, flanges, etc. Tapping machine plays an important role in manufacturing. Advantages of tapping machine: reduce working procedures and improve automation. The die internal tapping machine integrates the punching and tapping action of the parts to be tapped, and directly taps and punches on the punch simultaneously. Simple installation and convenient replacement: The die tapping machine is designed to be sturdy and durable, small in size, easy to install in different molds, and the tapping head can be replaced with different specifications. Standard precision thread. The tapping efficiency and accuracy of the tap can be improved by using an in die tapping machine, and the tap movement is in exact agreement with t

-

High precision tapping stroke is easy to adjust. The automatic reversing device can freely adjust tapping stroke. Shallow holes and low machined parts with holes can also be easily adjusted. The double safety device can prevent the damage of the screw tap. The double safety clutch is specially designed for spindle rotation, up and down, and tool advance and retreat. The spindle can automatically stop, and the reverse cutter retreat will not damage the tool. Pitch A and B gears are fully matched with the A and B rotating shafts and the main shaft according to the pitch, which are vertically stable, accurate and highly precise. The screws can move forward and backward freely without any effort when tapping. At the same time, it depends on excellent processing items, which will not cause different threads in thickness. Perfect threads can also be made for thin plates, light metals, synthetic resins and other soft products. At the same time, multi axis machine can be configured for multi a

|

|