Tapping machine is a kind of mechanical processing equipment that processes internal threads, screws or thread fasteners on the inner side of the holes of various parts with different specifications of through holes or blind holes, such as machine shell, equipment end face, nuts, flanges, etc. Tapping machine plays an important role in manufacturing.

Advantages of tapping machine: reduce working procedures and improve automation. The die internal tapping machine integrates the punching and tapping action of the parts to be tapped, and directly taps and punches on the punch simultaneously.

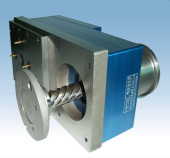

Simple installation and convenient replacement: The die tapping machine is designed to be sturdy and durable, small in size, easy to install in different molds, and the tapping head can be replaced with different specifications. Standard precision thread. The tapping efficiency and accuracy of the tap can be improved by using an in die tapping machine, and the tap movement is in exact agreement with the screw pitch.

Improve production efficiency: the use of die tapping machine can save working time, with high tapping accuracy, short time, and improve production efficiency.

Cost reduction: The use of die tapping machine can reduce the probability of material supply errors, reduce the amount of products in stock during processing, and thus save costs.

Energy saving: after the stamping and tapping of parts are combined, the tapping machine is completely mechanically driven, thus saving the machine energy specially used for tapping.

Labor saving: The die tapping machine combines tapping and stamping of parts into one process, which is fully automated, thus saving labor costs.

Reduce the defective rate: the accurate positioning of the die tapping machine can reduce the damage rate of the tap, and also reduce the probability of waste products due to feeding errors.