In recent years, China's auto parts industry chain has sprung up. With the social development, the traditional manual tapping production line has not been able to meet the expansion of market demand. Although the investment in the initial stage of mold opening is small, many problems such as the low efficiency of manual tapping and poor product quality stability after the completion of stamping have increasingly affected the development of enterprises. Therefore, it is urgent to develop automatic internal tapping of continuous die for stamping.

In China's traditional stamping automation industry, the market environment is deteriorating, no matter whether it is metal stamping at the bottom or auto parts stamping at the top. Many domestic manufacturers still use traditional manual tapping, which leads to low production efficiency. At present, there is still a certain gap between China's automation level and foreign first-line level. Therefore, the development of die tapping technology plays an important role in promoting the progress of China's basic manufacturing industry.

In China, many die tapping machine manufacturers have been widely used in the field of consumer electronics and household appliances, such as M3-M6 thread thread, which can be manufactured by many manufacturers in the industry, but they are faced with many bottlenecks in the auto parts industry, such as: the product thread is large, such as M6-M20, the production efficiency cannot meet customer requirements, the machine failure rate is high, the feeding is not accurate, the tap is easy to break, the tap is easy to burn, and the tooth is easy to break, The product blackens and cracks after tapping;

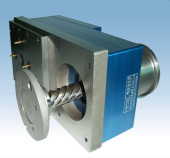

Huizhou Lixiang Metal Products Co., Ltd. focuses on breaking through the bottleneck technology of in mold tapping. It has developed and issued M1.0 Apple mobile phone accessories, in mold tapping+in mold return. After the return check, it will break the gap in the application of in mold tapping technology in the auto parts industry to make its products go global. In the international auto parts industry, most auto parts manufacturers prefer to import PRONIC in mold tapping. The products of this cooperation are auto parts of Yanfeng Johnson, This customer has also ordered PRONIC die tapping before, but after in-depth communication with the customer, the customer decided to order 2 sets of KDK-B series tapping machines from our company, which were successfully delivered to the customer for normal production, breaking through the gap in domestic die tapping applications in the auto parts industry, and the normal production speed was 30 times per minute.

Technical parameters:

Equipment used: 400T Ningbo Nianchu punch, stroke 300MM, NC feeder

Product material: S500-MC

Tapping size: 2 M8 * 1.25

Tapping direction: from top to bottom

Tapping speed: 30S. P.M

Minimum torque of tapping thread: 85Nm tapping oil is recycled, and tap life is 20000 times.